This pages were created as a reaction of the fact that within the

Applefritter-site a lot of threads are related to the topic of

the Apple-Disk II-

system. Due to the age of these diskdrives in a lot of cases they have

malfunctions... sometimes just by dirt, sometimes caused by

wrong

storage and sometimes just as the result of earlier bad treatment like

shocks or similar incidents.

So this pages will cover the entire topics of how this drives work, which

parts might become damaged and how to mantain this drives

by cleaning and adjustment. I will display pictures in detail with

markings inserted and comments to explain steps of service to

get that

drives running again in perfect shape. The order is related to the "toplist"

of malfunctions ( i.e. i will treat the topics in the order

sorted

how often the mistakes happen .... the most common first and the rather

rare mistakes thereafter ).

In the preliminary part i will first explain the way this drives work to

provide the user with some basic

knowledge..... this should be read too

because if you know how the drive works - you will know why you are doing

something and what the purpose of the task targets

for....

this will permit you to perform this tasks better by understanding the

task itself.

I hope this pages will become some kind of reference to the topic and

save in future a lot of redundant threads and help to keep this

drives

in good working condition.....

|

In the ancient days when this drives have been designed by Steve Wozniak,

the specialized chips for diskette-drives were horrible

expensive or not even designed ... so the Disk II -drive is equipped with

very simple logic chips from so called "standard series" ( i.e.

no specialized chips where used ).

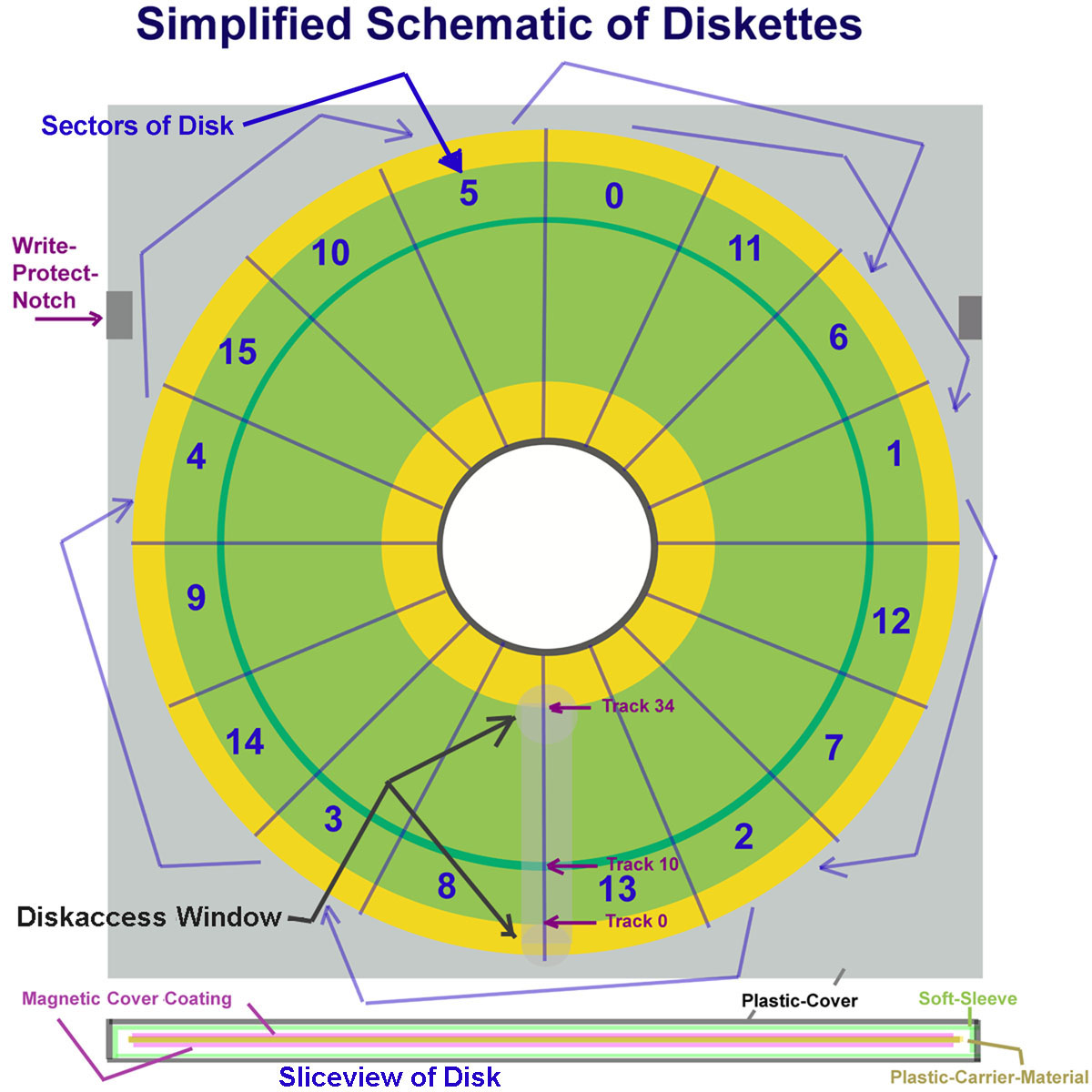

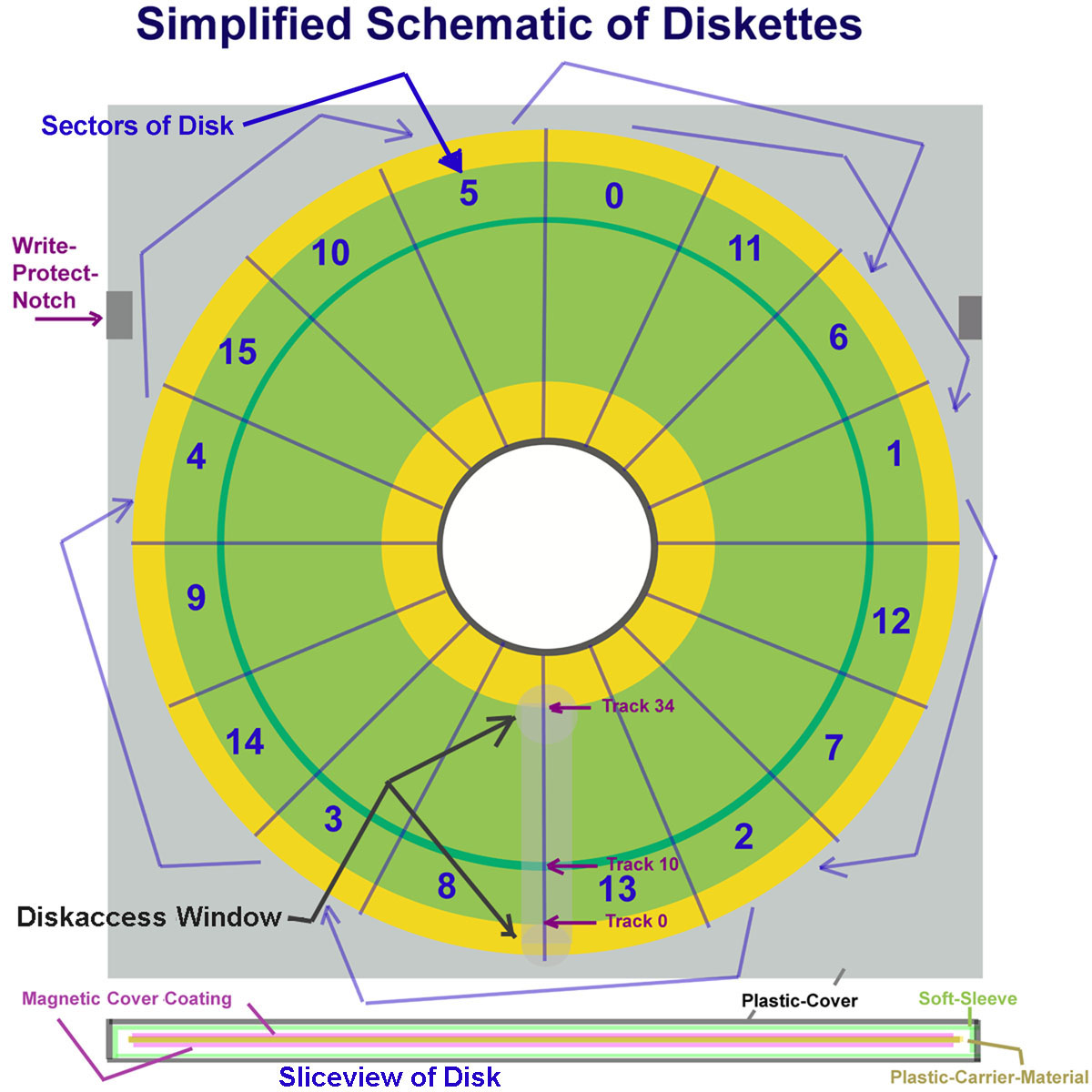

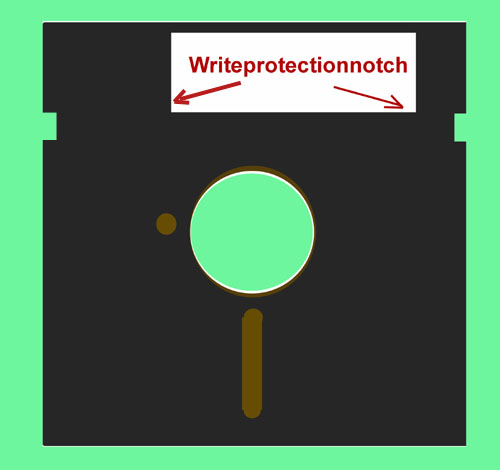

But before we examine the Drive and its components we first should take a

closer view to the diskette ( media ) itself - this is important

for understanding later explenations. So lets start with the following

shematic-picture and the explanations of the picture in the text

below:

|

|

After the first overview lets

examine first the so called "Sliceview of Disk" at the bottom:

the basical center of a diskmedia is a circle of

plastic-carrier-material

that is covered with magnetic cover coating ( one side at Disks marked

with "1S" and if both sides are covered with the material its

marked as "2S" .... - allthough

this is in very many cases not true.... a lot of diskettes marked as "1S"

are in fact coated at both sides, but for some reason ( mistakes

in the surface - or just

because it was to much work to change the manufacturing-line ) they were

marked with "1S". So it was a common habit in old days to

tryout, if the backside

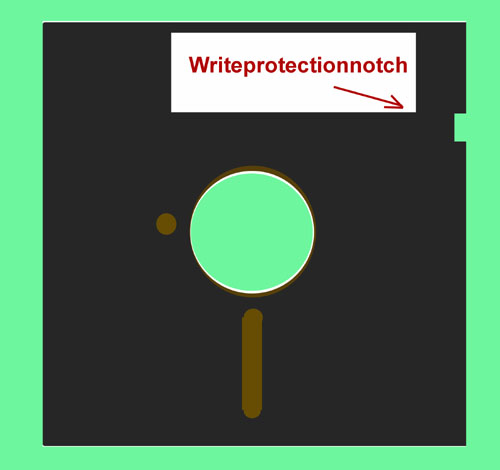

does work or not - and it therefor was also a common habit to punch a

read/write-notch in the cover with a so called

"Disknotchpuncher".

|

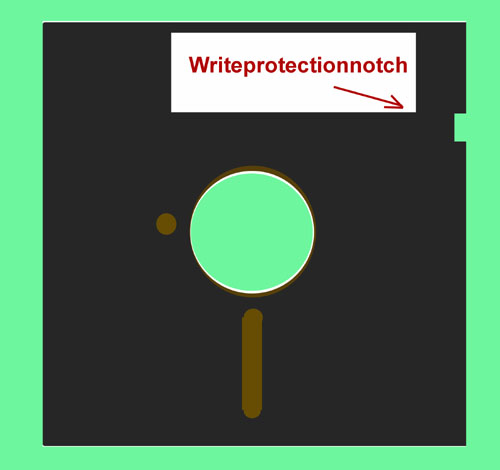

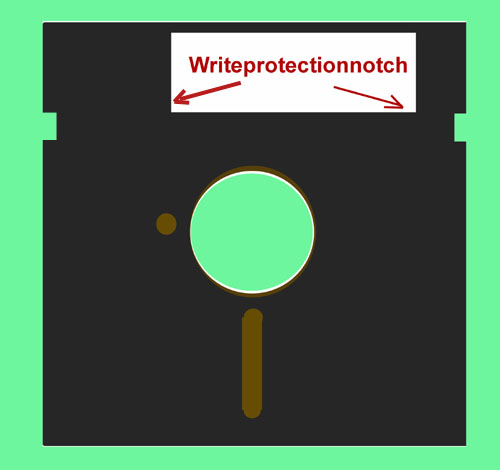

Disk with the common one notch for writeprotection |

Disknotchpuncher

|

Disk after use of the Disknotchpuncher |

|

|

|

That thin covered sheet of

plastic covered with a magnetic surface ( mostly on both sides )

is also marked to be "SD" ( for single Density = less quality of

magnetic-coating ) or as "DD" ( for Double Density = better

quality of magnetic coating ) .... there is also material sold

with marking "HD" used for Disks

with so called "High-Density" material - but this material can't be

used with any Apple Computer. It's "packed" in a soft sleeve to

avoid any kind of damage to

the surface. That "soft-sleeve" is within a cover made from thicker

resistant flexible plastic which is the cover you handle with

your hand.... - BUT:

Be CAREFULL ! In this cover is kind of

"window" which permits direct view to the basic-disk-material

itself - this is the window where the Read/Write-Head

slides along the material and reads the data - similar to the tape

- passing the readinghead in the recorder !

Never touch the surface of the Diskette

itself !!!

This can cause the diskette to become damaged severly and it gives

risk that dirt gets moved to the Read/Write-Head of the Drive

which is very extrem

sensible ! Back to the marking: 1SDD is for example single-sided

double-density.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Now lets take a look at the upper part of the picture: before

starting any discussion about spinning and orientation lets

agree to the following facts...

this picture is a view from the top of the Disk towards the bottom

of the drive ! So if you take a look to the diskturntable and

the drivebelt from botton to the

direction of the top of the drive the motor and the disk is

spinning clockwise ..... but - if you turn the drive around and

take a look at the disk from the top of

the drive of course the turningdirection turn to opposite (!) so

the disk turns in fact counterclockwise (!). So now you will

understand that the orientation of

the sectors of the disk are numbered correct ! Spinning the disk

around counterclockwise if the sector 0 passes the Diskaccess

Window the third sector to

become visible will be the sector with the number 1 and then after

another 2 sectors again the third sector will be the sector with

the number 2 and so on.....

This skipping of sectors in the order on the physical disk is

called "interleave". At the beginning it may sound crazy... but

this is really the fastest way to read

or write a disk ! To understand this we will examine very basically

the things that happen after a sector has been read or written:

After the Bytes have been read to the disk-controller and moved by

the cable to the computer and there moved to the memory and the

computer gave the

instruction to fetch the next sector ( and bear in mind that this

tasks require some time ! ) in the meantime the disk of course

has moved a bit ahead ( 2

sectors ) so at the beginning of the third sector the

reading-access starts just right again..... - just imagine the

interleave would not have been executed ...

in thet case the read/write-head would be above the sector with the

number 3 and it would need a delay of another 13 sectors till

the sector with the number 2

would be availiable again at the Diskaccess Window !

In the very beginning of the

Apple the diskettes were formatted with only 13 sectors - but

after very few years it turned out to be better to use a format

of 16

sectors. It is very important to recognize this fact ! The timing

of the interleave is only determined by a time-delay-loop that

is given by the software of the

proms ( P5 and P6 ) in the disk-controller ! So now at this moment

just the facts: the numbers of the Proms of the 13-sector

version of the controller show up

with : ROM P5 is labeled 341-0009 and the ROM P6 is

labeled with 341-0010. The Controller with the 16 sector version

contains the proms P5A labeled as

341-0027-A, P5A 1981 while the P6A is labeled as 342-0028-A,

P6A 1981.

This is an important thing to recognize - because it is impossible

to read or write 16 sector format with 13 sector proms as well

as it is impossible to read or

write 13 sectors with a set of proms determined for 16 sector

format ! The timing delay loops within the software just won't

match with the speed and

therefor won't match with the interleave-timing - no way !

Allthough in the picture above both - the yellow and the light

green area is covered with the magnetic-coating... but only the

green area is really used within

the Disk II. With the 40-track drives a larger part of the inner

yellow area is additionaly used too....

Important at the moment is just the fact that track zero is at the

outer side and the tracks with the higher numbers are orientated

towards the inner circle.

In another later part we

will switch back to this picture for more detailed view and

explanation .... but at the moment we can stay with the now

explained

knowledge.....

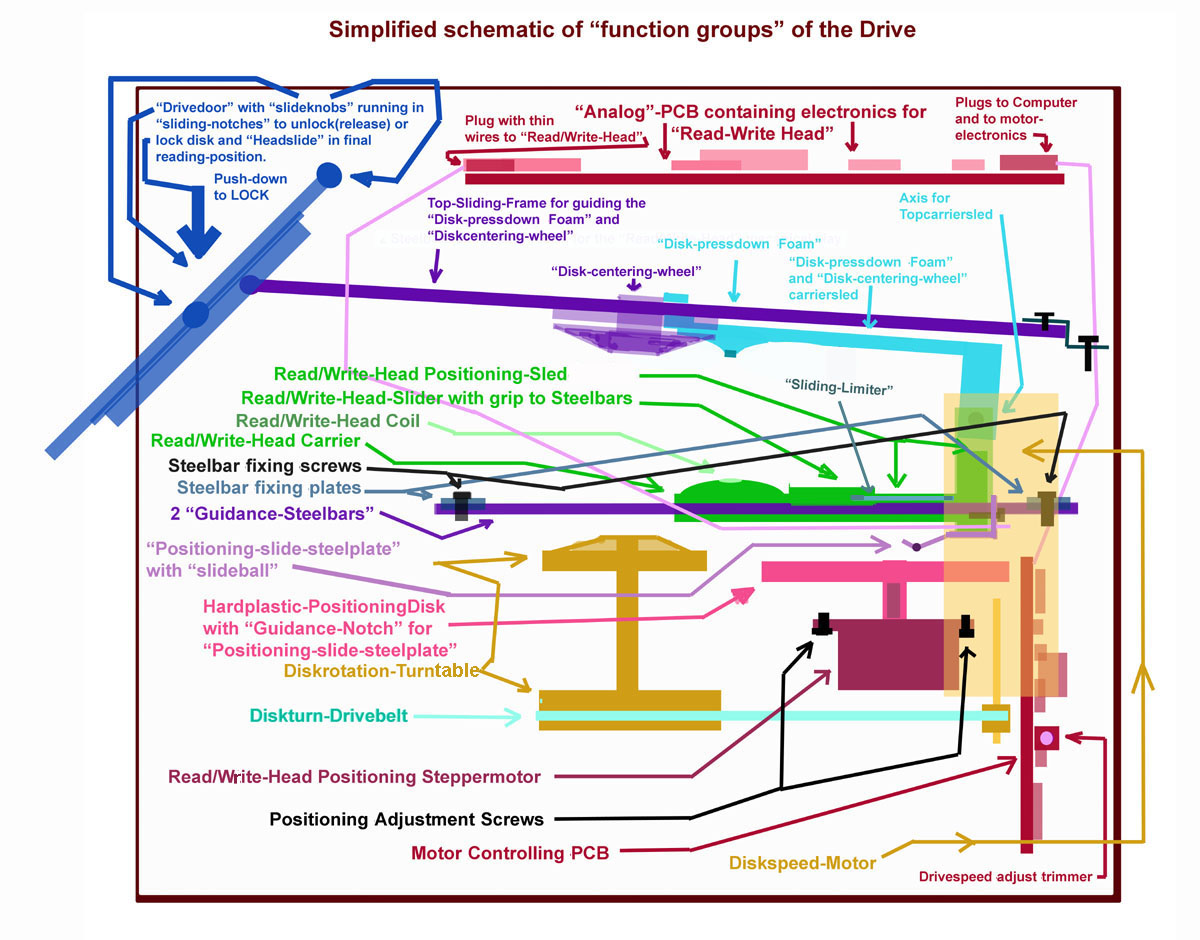

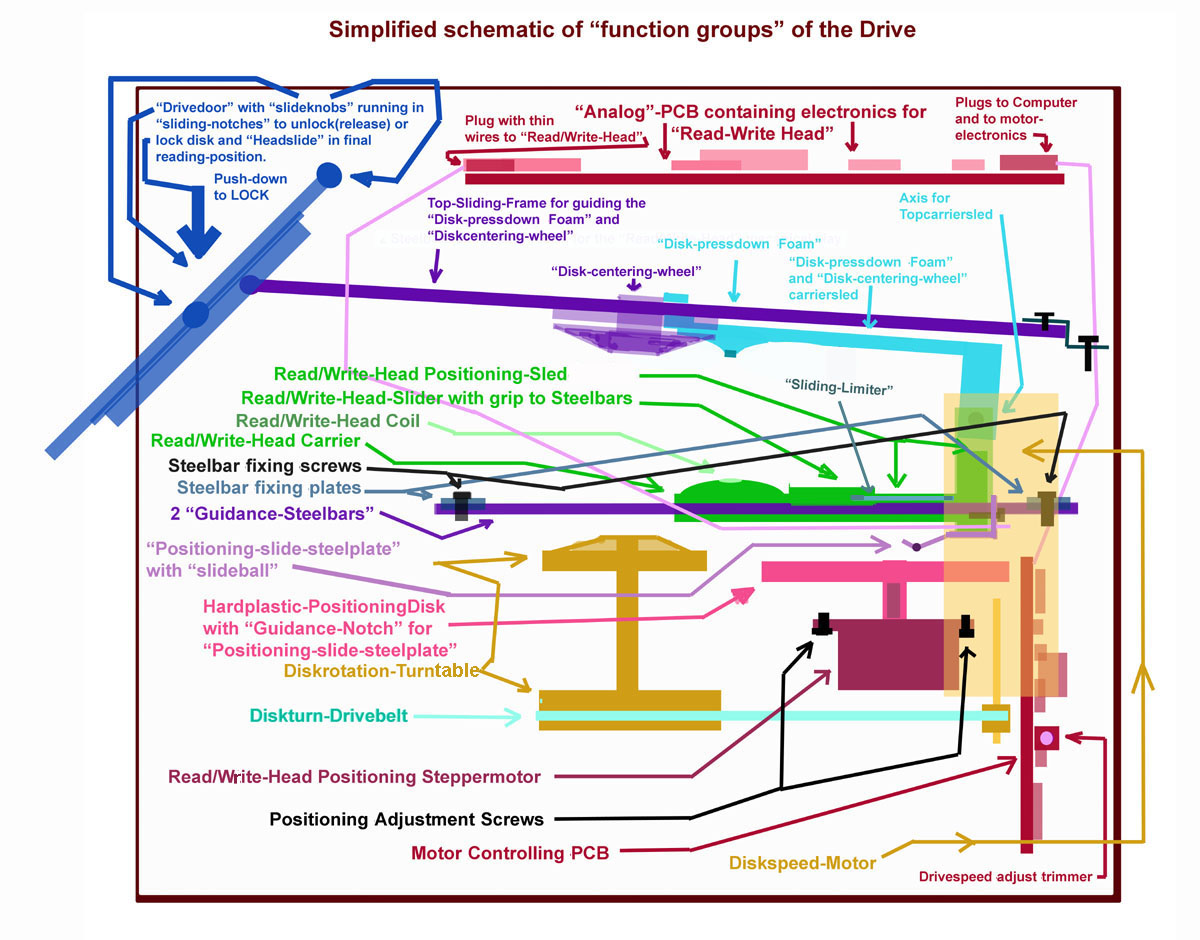

Now after the view to the diskette we can take a closer view to the

details of the drive. The schematic in the picture below shows

first of all a kind of

explosionview splitted to function groups that have been taken

apart to color groups. Colors similar to eachother belong

together. In the text below of the

drawing - the groups will be explained from the top of the drawing

down to lower levels towards the bottom of the drawing

....... after the explenations

this groups will be also documented with pictures that contain

additional comments in the pictures ....

|

|

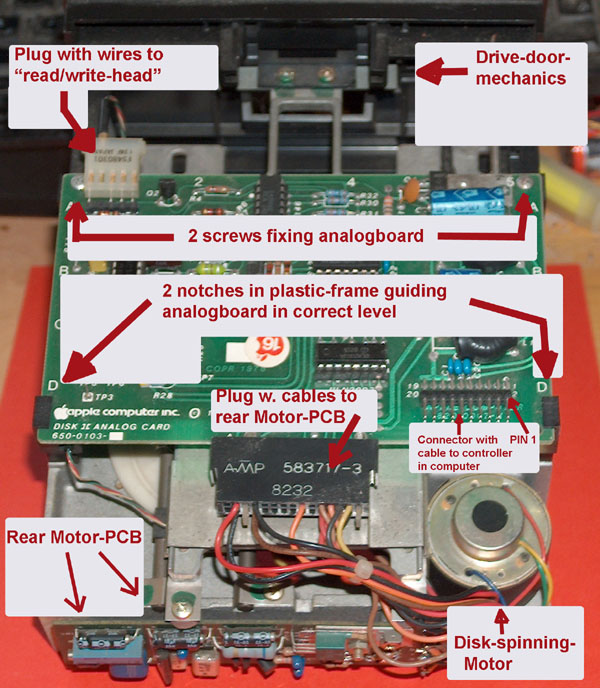

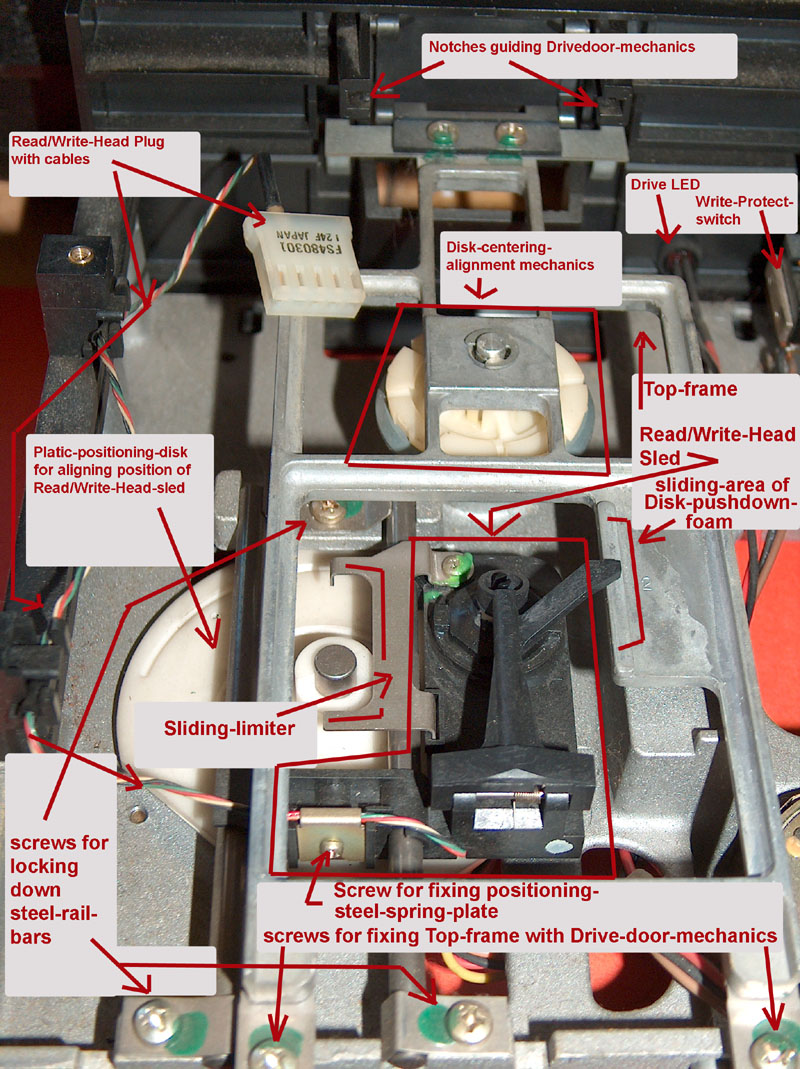

When you have removed the cover of

the DISK II - drive by untightening the 4 screws at the bottom

and sliding off the hood, you will first get the sight of the

so called "Analogboard". At the front left side there is a plug

with very thin wires - be very carefull with that wires - it's

the bunch of wires to the read/write-

head of the drive and they may not be damaged ! At the center of the

rearpart a very thick connector in the middle consists of a

bunch of cables that lead to

a PCB at the rearpart of the drive - which control the motor for spinning

the disk and the electronics to drive the stepper motor which is

responsible for the

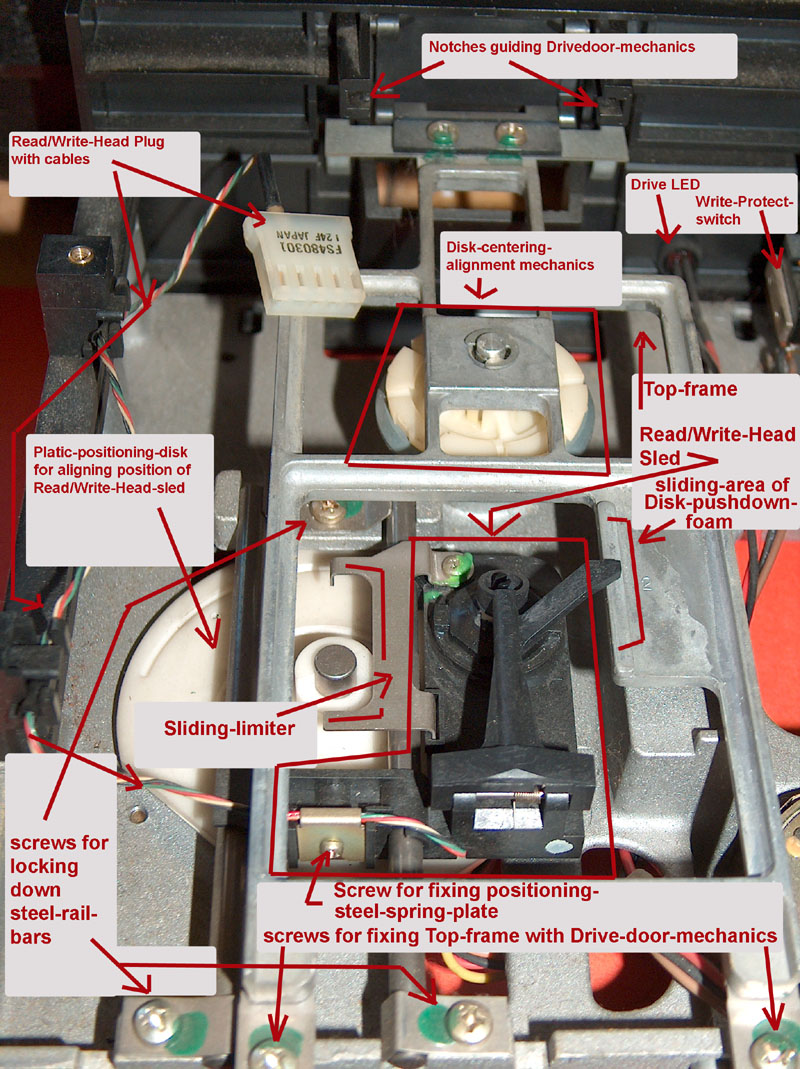

positioning of the "read/write-head sled". The "read/write-head-sled" is

not visible at the moment because its beneath the shielding-top

- it consists of 2 parts:

the top part the moves upward and downward by opening/closing the drive

door and the Steelframe where the sliding-mechanic runs along.

That steelframe

carries in the frontmiddle the mechanic for centering the disk in the

proper position when shutting the drive door, the upper part of

the sled with plasticpart

that i call the "Disk-pressdown-Foam" - if the door gets shut in front

with a disk inserted it gives light pressure to the disk to make

sure that it is fixed close to

the "read/write-head at the bottom part of the lower part of the sled. At

the one side of the sled there is a piece of steel mouted that i

call the "Sliding-limiter" -

this part makes sure that the "read/write-head" does not move out of its

disired bounderies. We will later take a closer examination to

this part of steel when

treating the task of positioning-mantainance.......

The analogboard is fixed at the rearside by running along within notches

of the plastik frame and at the front its fixed at both sides

with a scew.

So now at the moment first of all some pictures in the order what you

will see while dismounting the drive:

| View to the top of the

drive with analogboard in place |

|

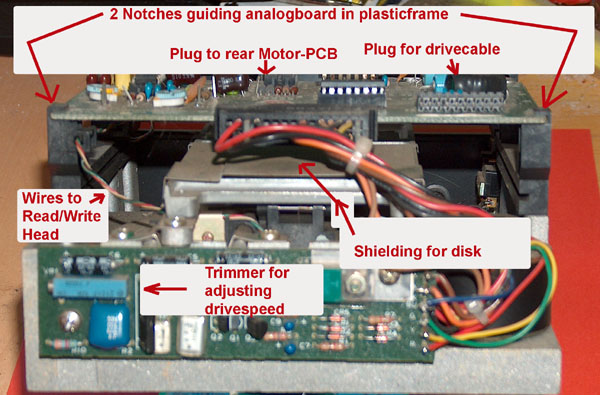

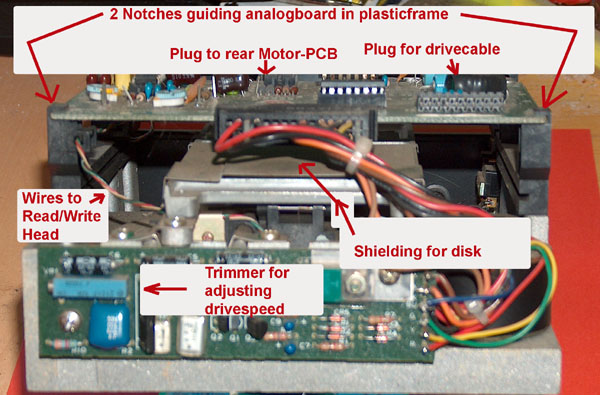

| View to the rear of

the drive with the analogboard in place |

|

|

|

| View to the Drive

after unmounting the analog-board |

|

|

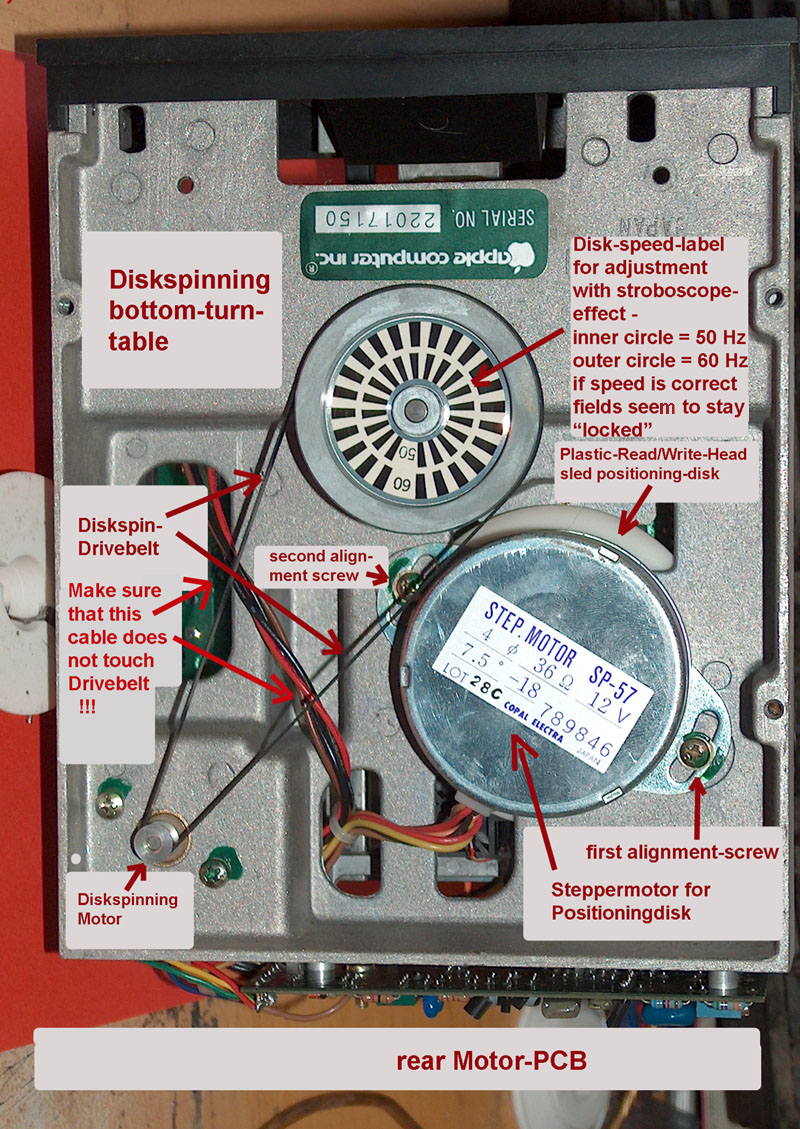

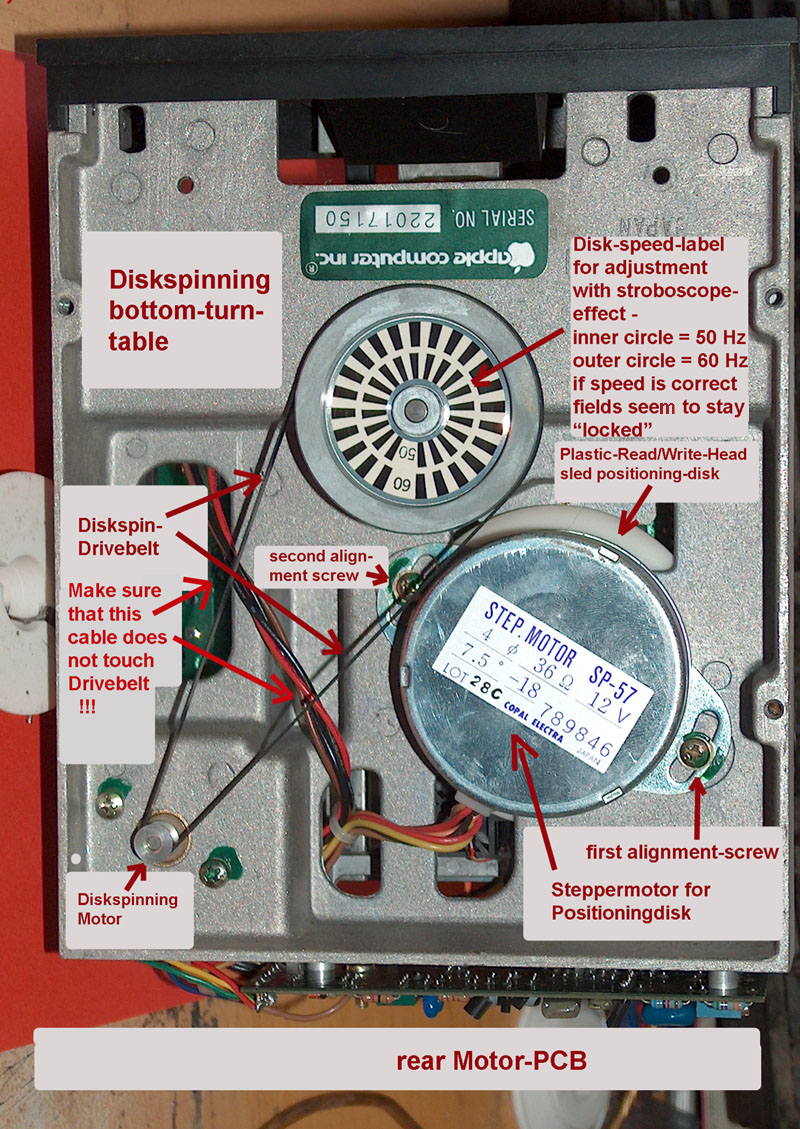

So now after this pictures lets

take a short look from the bottom of the drive to get some more

orientation on the components:

| commented bottomview

of the drive: |

|

|

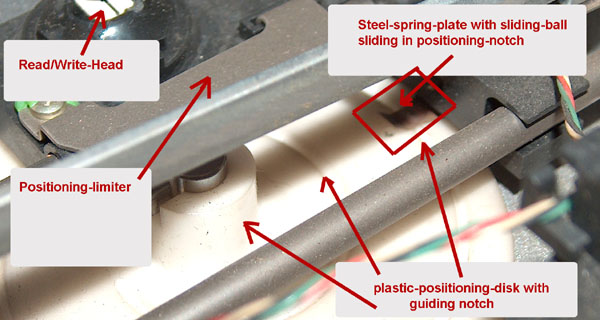

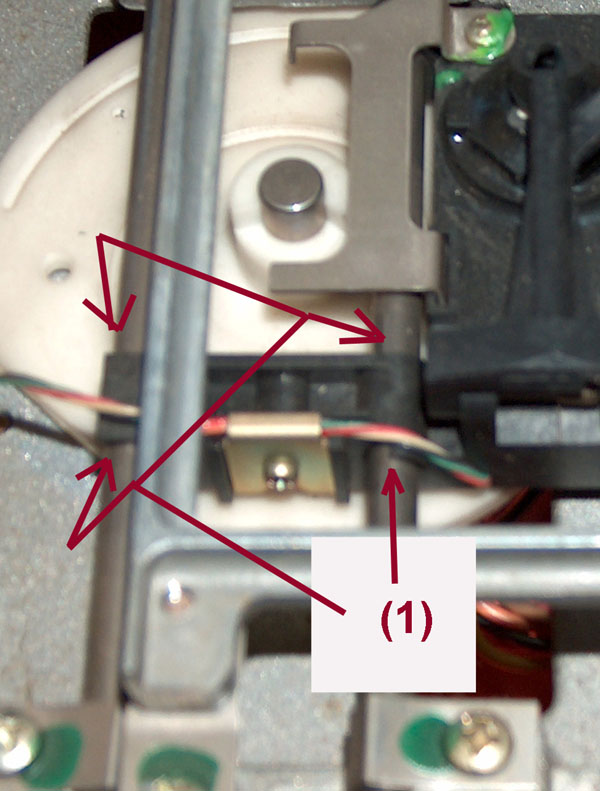

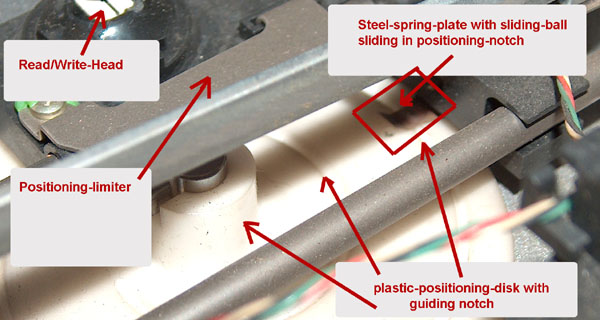

and to get the view

of the positioning-mechanic complete

here another detailed view of the steel-sliding

mechaninc

at the plastic-positioning-disk with close view

to the

steel-sliding-plate with the sliding-ball : |

|

So now some

additional remarks:

Up to this point the DISK II has been shown

that far that we can treat first the

typical mantainance tasks that could be

performed also at drives that are

working but are for example just noisy or have

minor problems resulting from

dirt or similar problems.

In the next part of the text and pictures i

will therefor explain this servicetasks

and i will treat the problems related with

calibration of speed and track zero

in the following additional pages to keep the

pages handy for fast loading -

at the end of this page there will be the links

to the page about calibrate speed

and a page about calibrating track zero.

Nevertheless i advice to also read the

following text and view the pictures too,

because after a repair it is recommended to

carry out the task of supplying

oil/grease to moving parts and cleaning the

read/write head to ensure proper

operation of the disk also in the future.

|

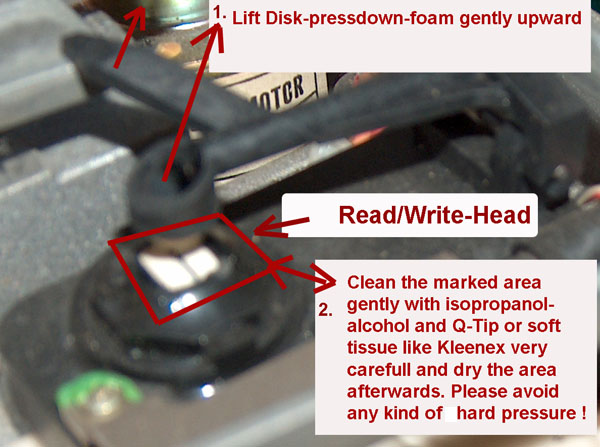

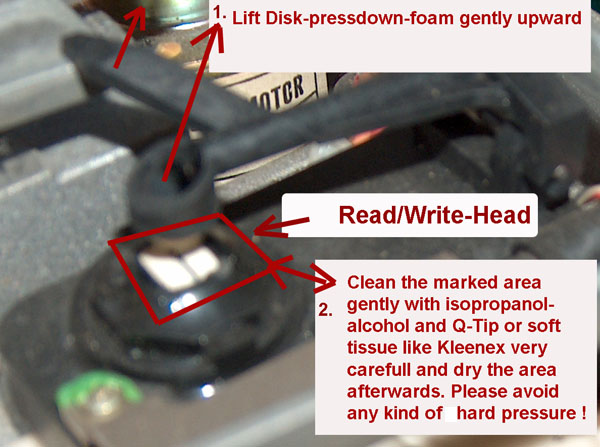

Cleaning the Read/Write-Head

|

|

|

|

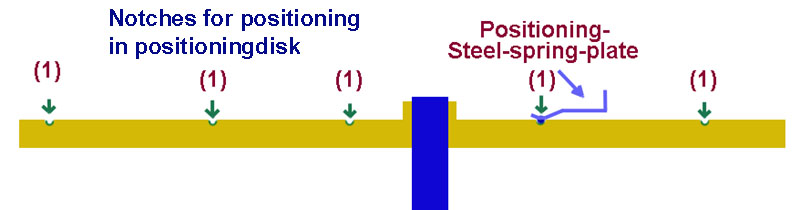

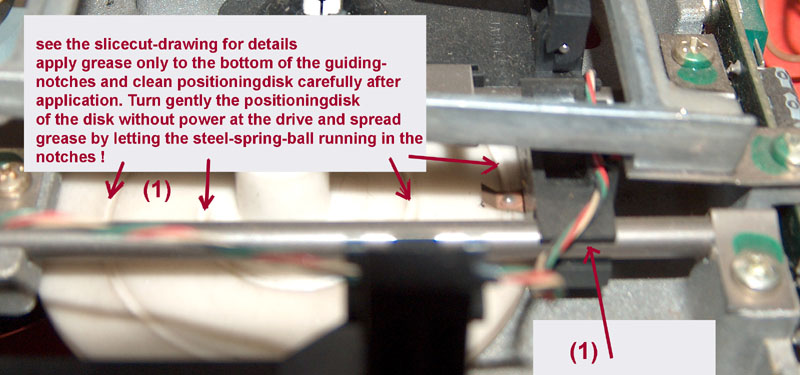

Getting the oil or grease to the right places and making sure

that it keeps there and only there !

first again a short explenation:

If you use oil ( specially if the oil is very liquid-fluent )

like the oil used in sewing machines isn't a very good idea.

First of all in the following time you

can't predict which directions the oil will start running to

after the drive was closed, where some drops might fall down (

i.e. onto the inserted disk ? )

and some kinds of oil have the bad habit, that they get thicker

like resine or vaseline and then they don't provide good sliding

attitude anymore.

The best experiences i have made with little more expensive

synthetic-grease as it is used for ballgears or

positioning-chains in robotic systems.

The consistency is quite similar to warm margerine, but it

doesn't drop around, but just is adhesive to the spots where it

has been applied to.

Such grease remains for years in the applied area and does not

change its attitude to keep a very slippy and smoth sliding

between the moving parts.

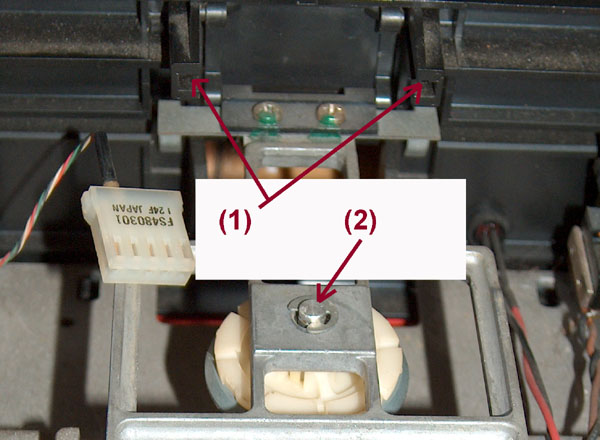

In the pictures below i will mark areas with

(1) or

(2). The marking with

(1) will mean that grease

should be applied ( only very few ) and the marking

(2)

will indicate where a very thin fluid oil should be applied.

|

|

|

download this page as

PDF-file

continue to next page about

speedadjustment of the drive

continue to the page about

calibrating the track zero

continue to the page about

advanced adjustment of the offset

of the electronical Read/Write-Head compensation cycle

common mistakes at the Disk ][ drive and the controller

making a homebrew replacement of the DuoDisk Cable |

|

|